Hollofiber is a synthetic non-woven material that is currently widely used for sewing clothes on winter time of the year. However, winters are different everywhere, so many people face the question: are holofiber jackets warm or not? And why else should you choose a model with holofiber insulation, and not, for example, the more familiar fluff.

Advantages of holofiber

Holofiber jacket - what is it? Such jackets are sewn from the same materials as down jackets, with the only difference being that synthetic material is used as insulation in the first version, and natural down in the second. Externally, the models can be absolutely identical. Many even mistakenly call holofiber jackets.

The advantage of holofiber as a filler is that it is cheaper than down. At no great cost, you will get yourself winter thing that can be worn for more than one season. Hollofiber can be easily machine washed, after the first wash it only shrinks a little, which does not affect its heat-saving qualities. Such a filler rarely causes allergies.

Another advantage of holofiber is a fairly long service life. Any fluff begins to fall off over time, and also crawl out through the fabric, and a jacket with artificial filling retains its original appearance. Although upper layer such jackets are made waterproof, it is possible that you will fall under heavy rain or snow. Hollofiber is not afraid of such vagaries of the weather, it dries easily and takes its original shape.

Disadvantages of holofiber

It is better to decide which jacket is better: down or holofiber, after familiarizing yourself with the shortcomings of this material. The main disadvantage of a women's holofiber jacket compared to a down jacket is weaker protection from the cold. Natural down is the most the best insulation, which most reliably protects the body from freezing. Hollofiber is suitable for fairly low temperatures, but in extremely cold winter conditions, which is not uncommon for us, this filler may not protect and warm you enough. However, it should be noted that down in down jackets, especially of low quality, can fall off and form voids without insulation, and holofiber is always evenly distributed throughout the thing. That is why many note the warmth of such jackets and prefer them to downy options.

|

|

|

|

The issue becomes very relevant in the cold season, which is very long in our latitudes. And as they say, there is no bad weather - there are bad clothes. Therefore, we will not complain about the bad weather, but simply choose the right clothes for ourselves, in which it is comfortable not only to run from home to the nearest stop or store, but also to take a leisurely walk on a frosty day without freezing. And it will be exactly what is filled with jackets, down jackets, coats that will warm us. What are the heaters-fillers and which one to give preference to? Let's find out.

Currently fillers for outerwear there are a large number. All of them can be divided into natural And synthetic.

Natural heaters:

1. Down- natural insulation, which has lightness and excellent thermal insulation.

A feather is added to the composition in order to evenly distribute the fluff over the product.

Manufacturers always indicate the ratio of down and feather in the insulation. For example: a value of 85/15 indicates that it contains 85% pure down and 15% feather. The fine feather prevents down from settling and rolling into hard lumps.

The most valuable down is eiderdown, then goose down. The most budget option is duck down, winter clothes on such a heater are not intended for severe frosts.

From shortcomings of such a heater, it should be noted the possible allergic reaction, as well as the difficulty in caring for the product, since after washing the filler still forms lumps.

2. Wool and fur- natural material  often used as a backing for winter clothes. It has high warming properties.

often used as a backing for winter clothes. It has high warming properties.

New Zealand sheep wool is considered one of the highest quality materials for the production of excellent wool insulation for children's winter clothes.

From shortcomings high absorbency and rather considerable weight are noted.

3. Batting - half-woolen insulation, which in the days of the Soviet clothing industry was used in the tailoring of overalls, as well as insulation for winter coats.

- half-woolen insulation, which in the days of the Soviet clothing industry was used in the tailoring of overalls, as well as insulation for winter coats.

Currently, such a filler is becoming less and less popular.

From shortcomings It is worth noting the large weight and fairly high water-retaining properties.

Synthetic insulation:

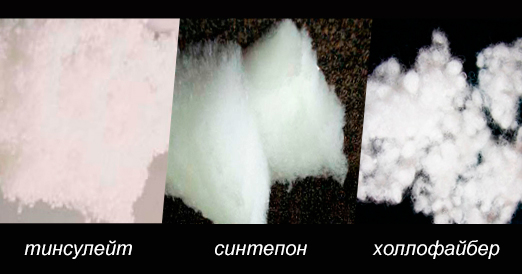

1. Sintepon- one of the most  common synthetic insulation. Consists of polyester fibers bonded with adhesive, needle-punched or thermally bonded. Lightweight, warm, inexpensive insulation was at one time very popular.

common synthetic insulation. Consists of polyester fibers bonded with adhesive, needle-punched or thermally bonded. Lightweight, warm, inexpensive insulation was at one time very popular.

However, due to a number shortcomings: increased moisture permeability, airtightness (the body in it does not breathe and fogs up), rapid deformation and fragility of the filler - it was replaced by other, better materials.

Now the synthetic winterizer is used as a heater for the production of cheaper demi-season and winter clothes. During washing, this insulation crumples, gets off.

And for a cold winter, it is suitable for a maximum temperature of up to -10 °.

2. Holofiber(hollow fiber) - non-woven fabric filled with synthetic fibers in the form of spirals, balls, springs, etc. This structure makes the thing warm, due to the fact that a lot of air is stored between the fibers.

2. Holofiber(hollow fiber) - non-woven fabric filled with synthetic fibers in the form of spirals, balls, springs, etc. This structure makes the thing warm, due to the fact that a lot of air is stored between the fibers.

This is a new generation heater. Lightweight, warm, moisture resistant, perfectly keeps its shape and hypoallergenic. An excellent material for the production of winter clothing insulation. Able to protect us from frost temperatures down to -25 degrees.

Varieties: polyfiber, thermofiber, fiberskin, fibertek, etc.

3. Thinsulate- one of the most expensive heaters. It is also called artificial down, due to its lightness and warming properties. But unlike fluff, thinsulate does not cause allergies and holds volume better without straying. It does not deform when washed, it is able to warm in frosts up to -30 degrees. Clothes on tinsulate are sewn for athletes, oil workers, climbers.

3. Thinsulate- one of the most expensive heaters. It is also called artificial down, due to its lightness and warming properties. But unlike fluff, thinsulate does not cause allergies and holds volume better without straying. It does not deform when washed, it is able to warm in frosts up to -30 degrees. Clothes on tinsulate are sewn for athletes, oil workers, climbers.

With the onset of cold weather, the question of choosing a winter jacket or coat becomes relevant. A down jacket should be warm, comfortable and not very heavy - these qualities are important for both adults and children. What are the fillers for down jackets? What filler will be better to keep warm, will not wrinkle and will not fall off?

Down - a natural filler for down jackets and what it is

For many years, down was used to insulate jackets and coats, sometimes in combination with feathers. Despite the development of technology, it is still considered the warmest, highest quality and easiest to care for filler. Please note - only waterfowl down is suitable for down jackets due to its water-repellent property. This allows it not to stick together, not to let in moisture and cold, and also not to absorb sweat. Before becoming a filler, fluff undergoes mandatory preparation procedures to maintain its properties throughout its service life. Thus, it is pointless to stuff the jacket with down on your own - the quality of the insulation will be low. In addition, factory processing makes the down hypoallergenic.

It is believed that best filler it's eiderdown. It guarantees warmth and comfort even in severe frosts and is suitable for long walks. Duck and goose down is the most popular filler. It is soft, warm and will last you a very long time. Swan down can be seen on the label is extremely rare. But fluff mixed with feathers, on the contrary, is often found on the shelves - the feather reduces the cost of the product.

How to understand that a down jacket is of high quality?

- Firstly, down is always placed in “bags” for even distribution - you probably noticed that down winter jackets are quilted. Each "pouch" contains the same amount of down, which gives the jacket a neat look and protects from the cold.

- Secondly, the down to feather ratio must be at least 75% to 25%, where the second value is the feather content. High-quality down jackets usually have a 95 to 5% ratio.

- Thirdly, good down jacket does not weigh more than 2 kilograms - after all, the fluff is almost weightless. In addition, such jackets fold compactly, and when unfolded, they restore their previous volume in a couple of days.

Good manufacturers of down jackets are the northern countries - Finland, Denmark, Sweden, as well as Canada and France and Italy. Local factories produce not only warm, but also stylish winter clothes. Russian down jackets are perfect for our climate, but are often inferior to foreign ones in design.

Companies with a history usually post information on the Internet about what kind of down is used to fill their jackets, where and when it is harvested, etc. On English-language labels, down is indicated by the word “down”, down + feather - “feather”. And if the word “intelligentdown” is written, then down was used to fill this jacket in combination with synthetic fillers.

On average, down jackets are designed for temperatures up to -30 °. Some models are also used in more severe conditions, for example, in Arctic expeditions. If you need a winter jacket for yourself or for a child, pay attention to its characteristics and make a choice according to the winter temperatures in your area.

How to care for a jacket with natural fill?

If your jacket gets dirty or you just want to give it a fresh look after the winter is over, the right choice is to take it to the dry cleaners. But many decide to wash the down jacket at home. Well, if you have the opportunity to do it manually. But, for lack of time or desire, we often throw winter jackets into the washing machine. What you need to know in order to wash successfully? Remember a few simple rules:

- when washing a down jacket with natural filler, you should follow the recommendations on the label;

- use liquid detergents - special shampoos for products with fluff;

- into the drum washing machine it is recommended to place 2-3 tennis balls - they will “break” the fluff so that it does not stick together;

- water temperature should not be higher than 30-40 °;

- the mode of manual or delicate washing is perfect;

- strong spin is contraindicated for down jackets - set the speed to a minimum.

After washing, place the down jacket on a horizontal surface, such as a bath board, and let the water drain. After that, shake the jacket well and hang it on a hanger. You can leave it to dry on its own or use a hair dryer or fan.

To store a down jacket, buy a cover for clothes. After washing and hanging the jacket on a coat hanger, place it in a bag and hang it in a dry place that gets fresh air. If this is a closet, air it periodically.

Wool as a down jacket insulation

Wool filler (camel or sheep wool) is often used to insulate autumn and winter jackets. The cost of such products is lower than with down filler, but at the same time they perfectly retain heat. Of the minuses - wool is heavier than down, so for a woman or for a child this option will be worse. In addition, cases of allergies to wool are not uncommon. And it shrinks when washed, so it is better to dry-clean such jackets. On labels, wool is denoted by the word “wool”.

Many manufacturers use a mixture of wool and synthetics, which makes the jacket easy to care for and allows you to wash it in the washing machine. In this case, the percentage of wool - “wool” - and synthetic filler - “polyester” will be written on the label.

In order for the item to retain its appearance and retain heat in the future, it should be washed at a temperature not exceeding 30 °, and the most suitable washing mode would be “Wool”. If there is no such mode, a delicate wash with a minimum spin speed and a mandatory additional rinse will do.

Synthetic fillers

The word "polyester" is a shorthand for any synthetic filling because they are all made up of polyester fibers. Some manufacturers do not specify the specific type of filler on the labels. When thinking about buying, ask a consultant in the store for details or look for information about the technologies for the production of jackets from this brand on the Internet.

Bio-down has been used since the 70s of the last century and is used for tailoring jackets designed for extreme weather conditions. On average, jackets filled with bio-down are designed for cold temperatures down to -40 °. Being an eco-friendly filler, it is soft and fluffy, resistant to wind and other external influences. Bio-fluff is light and voluminous, it is perfectly washable at home and does not roll into lumps. Artificial swan down is made from a new generation of microfiber. This material is not inferior in quality to natural fluff. The main advantages of artificial swan down are hypoallergenicity, softness, lightness and ease of use. It is remarkably washable and dries faster than natural fluff. Having bought a jacket with such a filler, you will feel comfortable even in severe frosts. Syntepuh has the same characteristics.

Thinsulate is a super thin fiber developed by 3M. This material has been successfully used for 40 years, including for tailoring clothes for astronauts. It is believed that thinsulate is one and a half times warmer than natural fluff. And it also perfectly retains its shape, has high water-repellent properties and dries quickly after washing.

Isosoft is also widely used - a Belgian insulation that is used for sewing adult and children's clothing and is designed for temperatures up to -40 °. Holofiber, polyfiber, fibertek and fiberskin fillers are united by one technology: they consist of ergonomic balls, spirals or springs, between which there are specially left gaps. This guarantees exceptional warmth and wearability of products with such fillers. Another plus - the cost of the jacket will be low.

Valterm is an Italian insulation with a honeycomb structure: it consists of many small cells and perfectly removes moisture. If you want to buy a jacket for winter sports, pay attention to this filler. It also removes moisture well and the primaloft insulation, which is used when sewing clothes for the US Army.

Membrane insulating down jackets

In the manufacture of sports and tourist jackets, membrane technology is used. The membrane - a thin film of special materials - is placed on the inside of the jacket if its purpose is to retain heat and remove moisture. How it works: snow and rain from the outside do not penetrate through the membrane cells, as they are very small, and the evaporation from the skin easily escapes through these tubules. This guarantees comfort and dryness of the body.

There is also a membrane spraying, in which the outer side of the jacket is treated with a water-repellent composition.

Caring for membrane jackets is easy. You will need a special composition for processing fabric with a membrane and a detergent recommended by the manufacturer for washing such jackets.

Men's and women's down jackets

Winter jackets for men are more often than women's, sewn using modern synthetic fiber as a filler. Men sweat more than women, so the issue of moisture removal is very relevant. For women, not only production technology is important, but also design, so many of the fair sex are guided, first of all, by the appearance of a jacket or coat. Now it is not difficult to buy a beautiful and warm jacket, the main thing is to carefully study the label.

Fur trims, embroidery and other decorations are more common on women's jackets. However, men's jackets, designed for harsh conditions, most often also have fur on the hood to protect the face from wind and snow.

Children's jackets

When choosing a filler for a children's down jacket, pay attention to the hypoallergenicity and lightness of the materials. The jacket should not constrain the child's movements. If the kid is fond of winter sports, give preference to technologically advanced synthetic fillers. Natural down is better for relaxing walks in the park and is guaranteed to be a suitable option if the child is still small and travels in a stroller.

Pay attention to the manufacturer's recommendations. So, some children's jackets at a temperature not lower than -5 ° are advised to wear a thin jacket. In a sweater and jacket, the child may sweat, which is fraught with the development of colds. It is better to buy two children's winter jackets - an ultra-thin down jacket for moderate cold weather and a technological jacket for severe frosts.

What is the difference between autumn and winter down jackets

When choosing a jacket for autumn, pay attention to the following points:

- the down jacket should be single-layer - it will be hot in a two-layer

- fluff can be less than 70% - in the autumn season it will only be on hand

- a down-free membrane jacket is a suitable autumn option, especially if you prefer active leisure

As a winter jacket, a two-layer down jacket with a down content of at least 75% is perfect. Synthetic insulation with suitable temperature characteristics is also good for cold weather. Sometimes manufacturers combine natural or synthetic fillers with a membrane - such jackets are especially good for those who spend a lot of time outdoors. If you move exclusively between home, car and work, it is not necessary to choose the warmest jacket. Assess the degree of your activity and decide which filler is best for you.

When buying winter clothes, you should pay attention not only to the style, fabric and finish of the product, but also to the insulating material, since it largely depends on it how comfortable, convenient and warm the jacket or coat will be. Hollofiber or synthetic winterizer: what will be warmer, more practical and more durable? To find out the answer to this question, you need to carefully study all the properties of these materials.

Sintepon: available warmth

A synthetic winterizer is a light, elastic, voluminous non-woven synthetic insulation that has been successfully replacing natural ones - down, feather and sheep's wool for several decades.

The technological process for the production of synthetic winterizer is based on the bonding of polyester fibers into a homogeneous fabric in one of three ways:

- Adhesive, using a composition of latex.

- Needle-punched - on machines with special equipment.

- Thermal - under the influence of high temperatures.

The latter method is considered the most effective, since the canvas becomes especially durable and dimensionally stable. The insulation obtained as a result of thermal soldering is called eurosynthetic winterizer.

The density scale of synthetic winterizer fabrics is quite large - from 40 to 1500 g / cm3. To insulate various products, they are laid out in layers and fastened together.

Interesting fact! Sometimes natural wool is added to synthetic fibers to increase heat-saving characteristics. The resulting material is called sherstepon and is used in sewing blankets and mattresses for strollers and cribs for small children.

Sintepon: pros and cons

The synthetic winterizer is a popular insulating material, since it has a number of positive properties:

- light weight compared to wool insulation and batting;

- resistance to various deformations;

- high thermal insulation qualities;

- low hygroscopicity;

- low melting point.

The undoubted advantage of the synthetic winterizer is the low cost of production, which makes all products with it democratically priced.

However, the synthetic winterizer also has negative qualities, and very significant ones:

- the use of adhesive compositions makes the insulation unsafe for the body, since, breaking down during washing, glue particles can cause allergic reactions;

- in the process of washing, the fibers of the synthetic winterizer stray into lumps, which are very difficult to “fluff”;

- the material does not pass air well, therefore synthetic winterizer coats and jackets are not suitable for especially low temperatures - you can freeze in them;

- synthetic winterizer fibers are able to "migrate" and seep through the upper fabric, giving clothes an untidy and unpresentable look;

- very often, second-rate raw materials are used for the production of synthetic winterizer insulation, which significantly reduces both the quality and the service life of products.

Nevertheless, synthetic winterizer is still one of the most popular insulating materials used in many industries.

Scope of application

Due to its operational and heat-saving characteristics, as well as the optimal price-quality ratio, the synthetic winterizer is used:

- in the production of upholstered furniture as a layer in sofas, armchairs, pouffes and other products;

- for sewing sleeping bags, tents and various tourist equipment;

- in the shoe industry for warming winter quilted boots;

- when tailoring outerwear - children's and adult jackets, coats, overalls;

- as a filler for blankets, mattresses and pillows;

- in construction - for the insulation of individual elements of buildings.

Interesting! Recently, synthetic winterizers have been used as a filter material for the installation of air systems, as well as in household air conditioners. Its fibers successfully retain even the smallest particles of dirt, completely purifying the air.

Product Care

Compliance with the rules for caring for things insulated with synthetic winterizer will significantly extend their service life and preserve their original appearance.

- Washing is best done by hand using liquid detergents that do not contain chlorine.

- It is impossible to soak clothes or bedding with synthetic winterizer.

- When washing in the machine, you need to select the mode for delicate laundry. The water temperature should not exceed 400C.

- Sintepon things do not twist. Clothes are loosely hung on hangers and allowed to drain.

- During machine washing, the spin and dry modes must be turned off.

- If the clothes need to be ironed, then this should be done carefully: set the iron regulator to minimum heat and iron through cotton fabric.

It's important to know! In order for the synthetic filler not to go astray during washing, it is recommended to put two or three tennis balls in the drum of the washing machine along with the clothes.

Holofiber: warm and fluffy

Translated from English, "holofiber" means "hollow fiber". Indeed, this innovative material consists of thin polyester fibers, inside of which there is air. It is its presence both outside and inside that provides the wonderful warming qualities for which this material is famous.

Each holofiber fiber is twisted into such a tight spring that it seems like a small ball. In general, the mass of insulation resembles a fluffy snowdrift or an air cloud.

The method for the production of holofiber was developed and patented in 2005 by the Moscow plant "Termopol", which produces several types of material:

- non-woven fabric - more often goes to the manufacture of outerwear;

- plates of various thicknesses - used in construction for insulation of structures, as well as in furniture production;

- balls are an indispensable filler for pillows, blankets and mattresses.

Even at the manufacturing stage, holofiber fibers are subjected to sterilization, therefore, in the future, during operation, they withstand not only numerous washings, but also hot steam treatment and even boiling.

Interesting to know! There is a technology in which polyester and silicone fibers are processed high temperatures in special heat chambers. The result is a "thermofiber" material, which differs from holofiber in its increased heat-saving properties.

Another modern insulating material, thinsulate, has similar characteristics. The difference between it and holofiber is that thinsulate is similar in its properties to natural swan or eider down - it is just as weightless and warm.

Characteristics

In terms of performance, holofiber resembles high-quality cotton, but unlike it, synthetic material is much more resistant to abrasion, does not stray into lumps and does not lose its original shape.

In addition, holofiber has the following qualities:

- high level of heat and sound insulation;

- breathability;

- increased elasticity and softness;

- resistance to numerous deformations;

- hypoallergenicity and safety;

- high elasticity;

- no static electricity.

Hollofiber is not subject to rotting, mold, pathogenic bacteria and microorganisms, does not accumulate odors, therefore it is an indispensable material in bedrooms and children's rooms.

Where applicable

Under the brand name "holofiber" many different products are produced. The most common areas of use for this insulation are:

- tailoring of outerwear - jackets, coats, overalls, raincoats;

- production of pillows, blankets and mattresses;

- production of upholstered furniture;

- filling children's toys;

- insulation of buildings under construction;

- air system filtration.

In addition, holofiber canvas is used even in the aviation and space industries.

Rules for the care of holofiber products

Jackets and coats with holofiber are as warm as down jackets, and it is much easier to care for these products. It is enough to remember a few simple rules.

- Hollofiber is washed by hand or in a typewriter; pre-soaking of products is not required.

- You can use a machine spin at low speeds and drying in a centrifuge.

- Hollofiber perfectly tolerates cleaning by any chemical means.

- After drying, shake the clothes vigorously enough to give them their original appearance.

- Ironing for holofiber products is not applicable.

It's important to know! If the pillow or blanket has lost its shape after long-term storage, it is enough to remove the insulation, fluff it up with your hands and put it back. It is for this purpose that most products with holofiber have a zipper.

What is better - synthetic winterizer or holofiber

After carefully reading all the characteristics of synthetic winterizer and holofiber, you can understand the difference between these two materials.

- Security. If the synthetic winterizer under certain conditions can release toxic substances, then the ecological purity of the holofiber allows it to be successfully used in the clothes or bed of a small child.

- Resistant to deformation. It is easy to recognize a synthetic winterizer product: after two or three washings, the filler “crumples”. Hollofiber retains its shape after dozens of stays in the washing machine.

- Thermal insulation. Hollofiber is warmer: in jackets made of it, even forty-degree frost is not terrible. The synthetic winterizer is mainly designed for the autumn-spring period, when the thermometer almost never drops below zero.

- Durability. A blanket, pillow or jacket with holofiber will last much longer than padding polyester.

The only advantage of the synthetic winterizer is its low price, but against the background of all of the above, it does not look very impressive.

In general, the choice of insulating material for outerwear, filler for home furnishings or bedding remains with the buyer.

What fillers for down jackets are used by manufacturers lately. What fillers in jackets to choose for yourself, your children and loved ones, so as not to freeze in the Russian winter? To answer this question, it is necessary to consider all new heaters, to study their properties and qualities. In the previous article "" we examined the most popular natural and artificial insulation for winter clothes.

We studied the types of natural fluff, feathers, wool and their properties, got acquainted with artificial heat-insulating materials such as synthetic winterizer, isosoft, holofiber, tinsulate, synthetic winterizer and learned their characteristics, advantages and disadvantages. But time does not stand still, manufacturers are trying to invent new and warmer fillers with improved properties. These include materials such as thermophile, fibertec, spray-bonded cotton wool.

Spray-bonded cotton wool insulation has been gaining more and more popularity lately. It is often used for children's jackets, overalls, for women's down coats, jackets. What this material is, how it is made and what it is made of, we considered earlier, but in order not to waste your time, let me briefly dwell on it again.

Spray-bonded cotton

Spray-bonded wadding insulation is classified as a natural material. It is made from cotton or cotton wool. The technical and operational characteristics of the filler spray-bonded cotton wool are close to the properties of biofluff.

Advantages of spray-bonded wadding:

- high wear resistance;

- high thermal insulation qualities;

- hypoallergenicity;

- does not crumple;

- breathable;

- environmental friendliness;

- a light weight;

- resistant to deformation;

- retains its properties even when wet.

Fibertec

One of the new heaters. Women's down jackets with fibertec filler are often found on sale, and it is also actively used for children's and men's jackets, overalls and down jackets. Fibertec is a non-woven material that is made from polyester fiber that has undergone siliconization. The fibers have a crimped shape, they are hollow inside, they are very thin, each of them is coated with silicone. Thanks to this, microfibers do not cake, they slide easily, taking up all the space. When deformed and crushed, the fibers quickly restore their shape. This filler of winter jackets is evenly distributed over the entire area of clothing, without creating freezing zones.

Modern fibertek filler has the following density: 200-400 grams per square meter. This is the optimal ratio of fiber and air. The presence of air chambers between siliconized microfibers provides excellent thermal insulation properties.

Fiberteck is produced in layers, 1.5-5 cm thick for the clothing and furniture industry. From it we sew everyday, work and special clothes. Clothing manufacturers often reinforce fiberglass filler with spunbond, creating a kind of sandwich. Spunbond is also a non-woven fabric made from polypropylene.

Fibertec advantages

- environmental friendliness, it is a hypoallergenic product; glue is not used for its manufacture;

- breathable, the material is breathable;

- high thermal insulation properties, protects from frost down to minus 40 0 С;

- antistatic;

- anticompression;

- light weight;

- wear-resistant;

- does not support combustion.

Comparison of fibertek filler with other clothing insulation

It is lighter, retains its shape better and returns it when deformed compared to holofiber. After washing, the fibertek does not shrink, it is minimal no more than 3%. These figures are 20% higher in comparison with synthetic winterizer.

With the same thickness, in terms of thermal insulation properties, it is inferior to thinsulate, but its price is lower.

The thermal conductivity of fibertec is 60% lower than that of wool felt, but inferior to static air by 19%.

As for care, you can wash clothes with fibertec filler not only manually, but also in a washing machine. For washing, the water temperature is 35-40 degrees. Dry clothes away from batteries and other heat sources.

Filler for down jackets Teplofil

Teplofil is one of the new fillers for winter jackets and down jackets. It was invented taking into account many years of production experience and the wishes of customers. It is a unique formula based on siliconized polyester insulation. Hollow synthetic microfibers are hollow inside, they form a complex system with many small air chambers.

Teplofil is one of the new fillers for winter jackets and down jackets. It was invented taking into account many years of production experience and the wishes of customers. It is a unique formula based on siliconized polyester insulation. Hollow synthetic microfibers are hollow inside, they form a complex system with many small air chambers.

Thermophilic microfibers fill the entire air space inside the down jacket and exclude the formation of cold bridges and hypothermia zones. The fibers are protected by silicone, they retain their properties even when wet.

The thermofil filler in the down jacket was created specifically for the Rusiand trademark. Insulation properties: light weight, "fluffy" structure, due to which the thermal insulation properties of the material increase (due to the presence of air between the silicone fibers), crease resistance, bulkiness. In addition, the insulation has good breathability, it will not be hot in warm winter weather and cold in the most severe frosts. Siliconized polyester jacket filler behaves perfectly during operation, it retains its volume and all its properties for a long time.

In down jackets with a thermophile, it will be warm and comfortable even at temperatures below minus 30 0 C. To further increase the thermal insulation properties of the product, some manufacturers use an additional fur lining. Women's, men's, children's jackets, raincoats and overalls with insulation based on siliconized polyester thermophile can be washed in washing machines. After washing, the insulation does not wrinkle, to give it its original shape, shake it well enough.

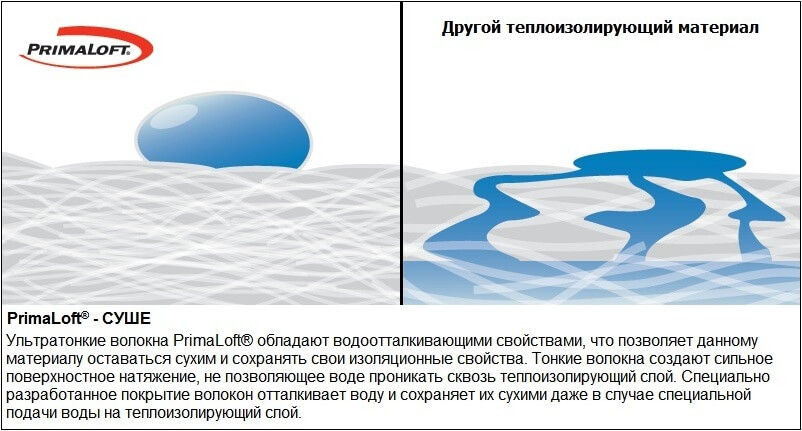

PrimaLoft

Synthetic filling for jackets, down jackets and autumn and winter clothes. This is an innovative product manufactured by Albany International. Filler Primaloft is another know-how in the field of production of thermal insulation materials. The technology consists in the combination of variable section fibers with long ultra-thin polyester fibers with a water-repellent coating.

Synthetic filling for jackets, down jackets and autumn and winter clothes. This is an innovative product manufactured by Albany International. Filler Primaloft is another know-how in the field of production of thermal insulation materials. The technology consists in the combination of variable section fibers with long ultra-thin polyester fibers with a water-repellent coating.

Thanks to innovative developments, PrimaLoft filling has been brought closer to the quality of natural down. This filler is boldly called an excellent imitation of fluff, it has the same highly porous structure, high elasticity. When crushed, the insulation quickly restores its original volume, and when wet, it retains its thermal insulation properties. It also dries quickly.

There are several more advantages of the material for filling Primaloft jackets and down jackets:

- light weight, it is light;

- does not get wet;

- breathable;

- removes excess moisture to create a comfortable microclimate inside clothes;

Manufacturers use a new insulation for outdoor clothing. PrimaLoft filler is actively used for tailoring hunters, soldiers, and fishermen.

Several types of PrimaLoft are used as a filler for down jackets and jackets. They differ only in the prefix: PrimaLoft ® One, Sport, Infinity. All of them differ in different fiber densities, different thicknesses, so they differ in terms of specific gravity, wear resistance and caking.

Several types of PrimaLoft are used as a filler for down jackets and jackets. They differ only in the prefix: PrimaLoft ® One, Sport, Infinity. All of them differ in different fiber densities, different thicknesses, so they differ in terms of specific gravity, wear resistance and caking.

Thermoball

Another modern clothing insulation that has recently appeared on the market. Thermoball® is a filler developed by PrimaLoft and The Nort Face. This material is created from fibers that resemble fluff in appearance. The structure of the filler is formed by rounded balls of Thermoball® PrimaLoft ® fibers. In terms of properties and characteristics, it is not much inferior to natural fluff. The advantages of such a heater include resistance to moisture, it dries quickly and does not wrinkle.

Another modern clothing insulation that has recently appeared on the market. Thermoball® is a filler developed by PrimaLoft and The Nort Face. This material is created from fibers that resemble fluff in appearance. The structure of the filler is formed by rounded balls of Thermoball® PrimaLoft ® fibers. In terms of properties and characteristics, it is not much inferior to natural fluff. The advantages of such a heater include resistance to moisture, it dries quickly and does not wrinkle.

Silver and Gold Insulation Down Blend

These are hybrid fillers developed by the manufacturer PrimaLoft ®. The material is a "gold" and "silver" line of thermal insulation materials based on ultra-thin fibers. Polyester fibers are mixed with goose down. Only the percentage changes: the “gold” series is 30/70, and the “silver” series is 40/60.

Gold and Silver Insulation Down Blend combine all the qualities of down insulation with the benefits of synthetic insulation. The result is a product with the highest efficiency and heat-saving properties. This filling is cheaper than natural down fills, light in weight, withstands the lowest temperatures and has high wear resistance.

What filler for a down jacket to choose, decide for yourself. When or jackets, pay attention to the characteristics of the material, its thermal insulation properties and wear resistance. If you live in a region with cold winters, then the first selection criterion should be heat-shielding qualities. Study the table!